Bussiness

The role of mobile robot manipulators in industrial automation – London Business News | Londonlovesbusiness.com

Industry 4.0 focuses on using the power of advanced technologies like AI, IoT, advanced sensors, robots, etc., to shape smart factories for the future. Modern industrial production requires higher flexibility to respond to the shifting consumer demands quickly. Mobile manipulators play a critical role in offering higher flexibility, adaptability, and collaboration in industrial processes. The global mobile manipulator market is valued at 513 billion US dollars in 2024 which is expected to reach 1208 billion US dollars by 2030.

In this article, we will go through the applications of mobile manipulators, their roles in different industries, and the future trends in the domain.

Key application of mobile robot manipulators

Material handling and logistics

A mobile robot manipulator automates the material handling tasks like loading, unloading, inventory management, etc. These robots can transport goods across the facilities and place them in the right spots without any unnecessary errors.

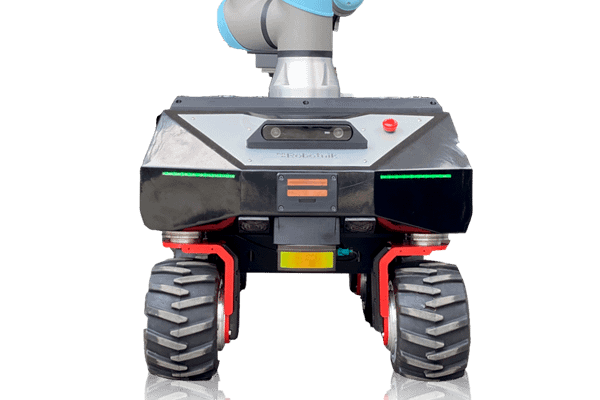

Robotnik develops a wide range of mobile manipulators for the development of industrial applications and boosts R&D in the Service Robotics domain. Its RB-KAIROS+ model is an ideal choice for material handling to reduce manual labor and speed up overall order fulfillment.

Packaging and sorting

The robots have the ability to identify the products through their vision system and place them properly. Companies can use them to sort, package, and label diverse products which improves order accuracy.

Assembly line automation

The tasks in the dynamic assembly lines change in a frequent manner. The robotic mobile manipulators are ideal to handle the tasks as they can be reprogrammed to adapt to the evolving processes on the assembly line.

Quality control and inspection

Mobile manipulators with advanced sensors and cameras can inspect the parts and finished products precisely. They can identify potential defects and check all the components that are placed in hard-to-reach regions. Also, these units can move around the production area freely.

Collaborative robotics

Mobile manipulators can be programmed to work alongside humans to increase productivity and safety. They can handle the heavy components and deliver the right tools to reduce the overall strain on human labor.

Role of mobile manipulators in different industries

Aerospace and defense

Mobile manipulators can handle delicate material, assemble components, and perform hard maintenance tasks in the aerospace and defense industry. These smart robots increase the precision level, reduce human error, and improve safety when working in dangerous environments. Also, these units can automate quality inspections and assist the experts in the complex assembly processes.

Logistics and warehousing

From picking heavy loads to sorting the items in the warehouses, mobile robot manipulators can automate all the tasks for the logistics and warehousing industry. These units can work in any environment and handle all the material properly which minimizes downtime. They can work with the in-house staff to reduce labor-intensive activities. These robots can pick and place the items in the right place which further optimizes the storage spaces for the businesses. E-commerce companies use mobile manipulators for high-speed sorting of packages based on size or destination which further improves the order accuracy.

On top of this, these robots can integrate with inventory management systems to provide real-time stock updates and avoid events of overstocking. When the demand rises for particular products, these robots can help companies automate the loading and unloading tasks for better order fulfillment.

Manufacturing

When it comes to the manufacturing industry, the robot manipulator automates repetitive tasks like assembly, quality control, etc. Their high precision level reduces the risk of defects in the products and speeds up the entire production cycle. With this ability, companies can meet high-volume demands without any unnecessary stress.

Besides all this, the robots can adapt to new tasks quickly which makes them ideal for flexible manufacturing environments. The best thing is that they improve worker safety in the industry by taking control of hazardous operations like working with heavy machinery, handling toxic chemicals, etc.

Healthcare

Mobile manipulators are transforming the healthcare industry by automating essential tasks like medication delivery, patient assistance, sanitation, etc. These robots can work around the hospitals without any issues and reduce the workload on medical staff. The robotic arms can assist in surgeries, therapy, and lab operations and increase the precision and reliability of results. They also improve the safety levels by handling biohazardous materials and sterilizing equipment.

As healthcare facilities focus on efficiency and hygiene, mobile manipulators can improve the overall service quality and help healthcare facilities focus on higher efficiency and better hygiene.

Agriculture

Businesses in the agriculture industry can benefit from mobile robot manipulators. They can help them reduce labor costs and increase the total yield by working with higher efficiency across large fields. These robots don’t need to rest so they can work in harsh conditions for longer durations. Also, they can collect data on soil conditions, crop health, and other important metrics through their advanced sensors and allow the farmers to use proper farming techniques for better yields.

These units can automate several tasks like planting, crop monitoring, harvesting, etc. With the demand for sustainable farming on the rise, these smart robots can help farmers and businesses in the industry to optimise resource usage and get better productivity.

Future trends in mobile robot manipulators

AI-driven decision making

With the power of AI, mobile robot manipulators can operate autonomously and adapt to real-time conditions. These robots can leverage machine learning algorithms to optimize paths, allocate tasks, and predict maintenance needs. These things improve the efficiency and reduce the overall downtime. These smart units can analyse data from sensors, detect patterns, and respond quickly to changes in the environment. This trend is necessary for Industry 4.0 to offer smoother operations, higher precision, and seamless collaboration with other automated systems.

Sustainability

Sustainability is another core focus in industrial automation. Companies are developing energy-efficient designs for robot manipulators that will reduce overall energy consumption and wastage. Also, they are investing in eco-friendly materials to create greener robotic solutions that can help the brands in different industries align with global sustainability goals.

Customisation

Modern industries demand customized mobile manipulators that have the ability to adapt to specific needs. Companies are developing robots that can handle unique tasks and offer a higher degree of flexibility. These customized units will help them adapt to the changing market needs with an agile and responsive approach that will lead to productive and cost-effective processes.

Autonomous fleet management

Businesses can use autonomous fleet management to deploy and monitor multiple mobile robot manipulators at the same time. This will increase the degree of coordination and efficiency. Companies are investing in R&D to develop smarter fleets of robotic manipulators to improve their collaboration with other automated systems. They are developing smart fleet management systems that will reduce the bottlenecks on the factory floors and order all the logistic processes. This will raise the total productivity and operational scalability.

The bottom line

Mobile robot manipulators are revamping traditional processes and helping businesses to adapt to the dynamic market demands properly. Some challenges are limiting the growth of these units but companies are using the advanced technologies to create better solutions. As all industries move toward smart manufacturing practices, mobile manipulators will soon become a necessary asset to stand strong in the market.